ITTS co-creation with Advantech to provide the iFactory solution from OT layer, IT layer to DT layer in Electrical Machinery Industry.

Many manufacturers are facing the critical period of digital transformation, and are trying to evaluate various technologies to make factories comply with Industry 4.0 standards. Through Industry 4.0 technology are used in combination with other equipment and sensors, they become key factors in identifying patterns related to equipment productivity, efficiency, maintenance, and of course failure. ITTS has a wealth of domain know-how and deployment experience of smart factories in the electromechanical industry. We co-creation with the leading industrial computer provider Advantech to provide the electrical machinery industry with a complete WISE-IoT Suite platform running iFactory application solutions. Through the cloud control of important components such as electric motors and related equipment, the process can be monitored at all times and any potential failures can be detected in advance. The benefits include keeping motors and equipment running at maximum efficiency, performing when required, avoiding costly repairs when equipment is down as well a reducing operating cost.

ITTS provides end-to-end smart factory solutions from equipment and machine connection (OT layer), company or factory management (IT layer) to the war room/business predicting (DT layer). At the OT layer, combining Advantech's expertise in automatically connecting hardware equipment and sensors.

iFactory @ Electrical Machinery Solution Structure

iFactory @ Electrical Machinery Solution Introduction

iFactory solutions are aimed at the electrical machinery industry, providing package content including iFactory @electrical machinery industry application solutions on Advantech’s WISE-IoT Suite platform, assisting the electrical machinery industry in building a digital operation center, and providing iAPP cloud applications including Preventive Maintenance System (PMS) and Overall Equipment Effectiveness (OEE), Andon application, and Shop Floor production line on-site management system, etc., are quickly imported through the cloud system package to improve production efficiency and accelerate the digital transformation of the electrical machinery industry.

I.App Solution Suite

|

Preventive Maintenance System |

Overall Equipment Effectiveness |

Andon |

Shop Floor |

|

|

Preventive Maintenance System Preventive maintenance is an important part of facilities management. PMS contributes towards improving efficiencies by avoiding downtime and malfunctions. Plan and schedule your maintenance activities then analyze the result to decrease the probability of assets failing. |

|

|

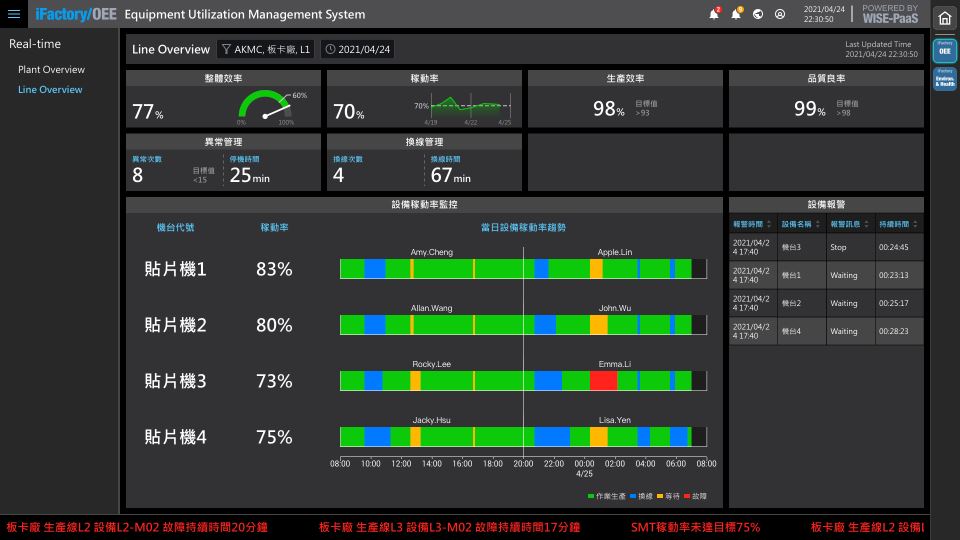

Overall Equipment Effectiveness Visualized monitoring of OEE indicators and KPIs of the whole plant through data acquisition, aggregation, and machine utilization analysis. Smart factory production efficiency management can be easily realized to increase productivity, review, and analysis of major losses, improve equipment utilization, and effectively increase production capacity. |

|

|

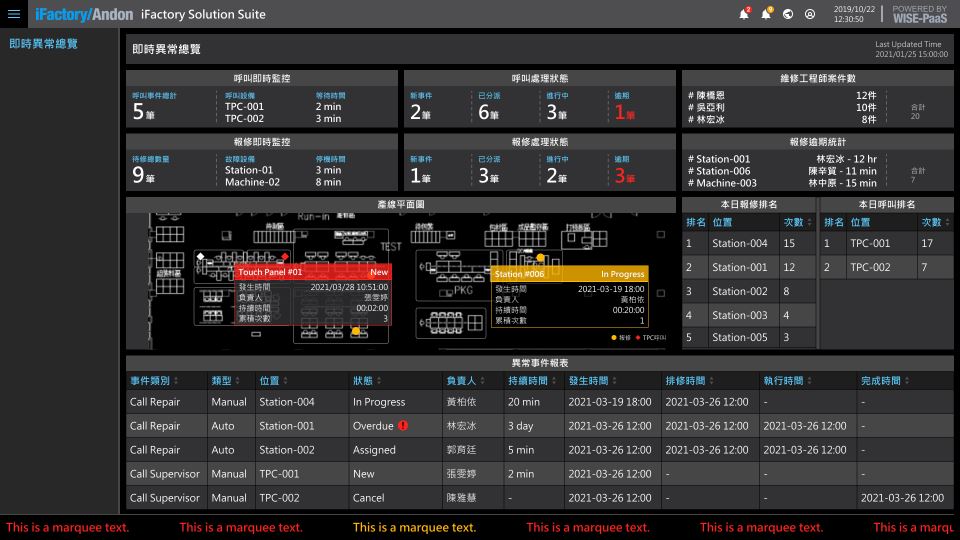

Andon Andon system is an alarm system that can improve the response time of supervisors or technicians by triggering signals when issues happen in the manufacturing process. |

|

|

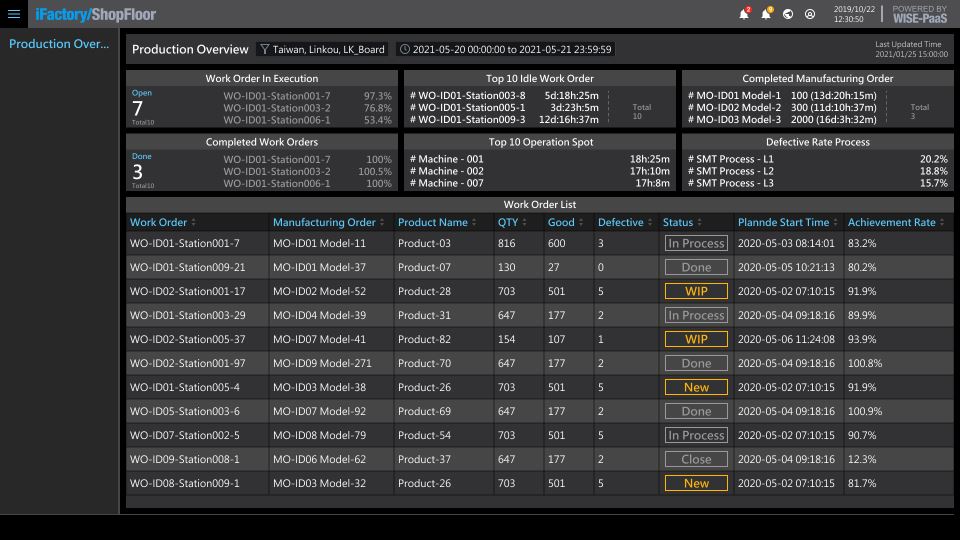

Shop Floor A manufacturing management system for real-time production tracking, scheduling, and status reporting of work orders or operations, which improves progress control for supervisors. |

iFactory Advantages

iFactory Solution suite @ Electrical Machinery Industry demonstrates the value that digital acceleration can do to the industry. iFactory Technology seamlessly provides the data and insights companies need to enhance digital and

➢Hotline: (886-2)5551-9890

➢E-mail: services@itts.com.tw